Grasping In-Mold Decorations: Strategies, Fads, and Finest Practices for Optimum Results

In the world of manufacturing, the art of in-mold decors stands as a pivotal aspect of product layout and production. In-Mold Decorations. By diving right into the approaches, patterns, and finest methods that underpin effective in-mold design procedures, businesses can open a realm of opportunities that not only boost the aesthetic attraction of their items but additionally simplify production efficiency and strengthen customer involvement.

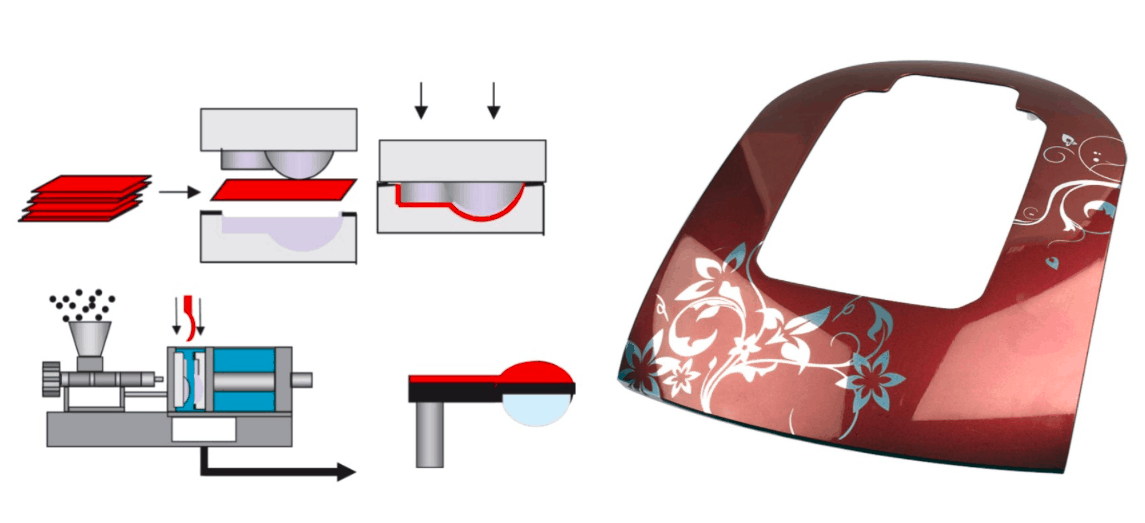

Material Choice

Product selection is a critical facet of mastering in-mold decorations, as it directly affects the top quality and durability of the final product. When selecting materials for in-mold decorations, it is vital to think about elements such as compatibility with the molding process, the wanted visual result, and the environmental conditions the item will certainly face. Polycarbonate products like abdominal muscle, polycarbonate, and polypropylene are commonly made use of for in-mold decors because of their flexibility and ability to attain intricate styles. These materials use outstanding moldability, enabling suppliers to produce complicated shapes and patterns with precision.

Furthermore, products with high warm resistance are favored for in-mold decors, especially for items that will certainly be subjected to raised temperature levels throughout their lifecycle. By very carefully selecting the suitable material for in-mold decorations, manufacturers can enhance the overall quality and durability of their products, fulfilling the assumptions of both end-users and clients - In-Mold Decorations.

Design Development

An essential factor in advancing the area of in-mold decors is the constant exploration and execution of layout technology techniques. Style development plays a vital function in enhancing the visual appeal, capability, and general high quality of items made making use of in-mold design processes. By including cutting-edge style components, suppliers can separate their products in the market, bring in customers, and stay in advance of competitors.

One of the vital elements of design technology in in-mold designs is the integration of intricate patterns, structures, and graphics that were formerly challenging to attain with standard decoration approaches. Advanced technologies such as 3D printing and digital style tools allow designers to produce complex and detailed layouts that can be effortlessly transferred onto molded components. Furthermore, making use of vivid shades, metal surfaces, and unique effects like gloss or matte structures can further boost the aesthetic appeal of in-mold enhanced products.

Moreover, layout development expands beyond looks to include useful improvements such as ergonomic forms, incorporated functions, and personalized elements that accommodate details user requirements. By embracing layout innovation, makers can open brand-new possibilities for personalization, item, and creativity differentiation in the affordable landscape of in-mold decors.

Production Efficiency

Efficient production processes are vital for converting the innovative designs developed in the field of in-mold decorations into top notch finished items that fulfill market needs and customer assumptions. In the world of in-mold decorations, manufacturing effectiveness includes different crucial elements that contribute to the general success of the manufacturing process. One important aspect is the optimization of mold design and tooling to ensure precise and smooth decoration transfer onto the final item. By fine-tuning mold and mildew arrangements and purchasing high-grade tooling materials, makers can improve efficiency and consistency in manufacturing.

In addition, applying automation and robotics in the production line can significantly boost effectiveness by streamlining recurring tasks and reducing the margin of mistake. Automation not only increases the production procedure however additionally boosts precision and repeatability, bring about a much more top quality and consistent output. Adopting lean production concepts, such as just-in-time inventory administration and waste decrease strategies, can additionally improve production effectiveness by decreasing downtime and optimizing resource use. Overall, a holistic technique to production efficiency is vital in optimizing the potential of in-mold decoration techniques and attaining ideal cause the affordable market landscape.

Quality Control Measures

What are the crucial strategies for ensuring stringent quality control measures in the world of in-mold decors? Quality assurance actions are paramount in in-mold decoration procedures to make sure the manufacturing of perfect and premium finished items. One vital method is the application of rigorous examination procedures at every stage of the manufacturing procedure. This includes conducting detailed aesthetic evaluations, dimensional checks, and color uniformity assessments to recognize any inconsistencies or flaws early.

Utilizing innovative technologies such as automatic inspection systems can likewise boost the quality control procedure by offering exact and dependable data for evaluation. These systems can discover blemishes that may be read this article missed out on by manual evaluations, therefore improving total item high quality and consistency.

Routine training and growth programs for employees associated with the in-mold design procedure can additionally add to keeping top quality standards. By informing personnel on best techniques, quality expectations, and the value of focus to information, companies can foster a society of quality consciousness throughout the organization.

Consumer Charm

To boost the bankability of in-mold decor products, understanding and providing to customer choices play an essential function in establishing their allure and success. Customer allure in in-mold decors is affected by numerous variables, including style appearances, shade selections, durability, and overall more functionality. Consumers are significantly seeking personalized and one-of-a-kind items that mirror their uniqueness and style. Offering modification choices such as customized designs, shade variations, and textural aspects can significantly boost the charm of in-mold decoration items.

Verdict

In-mold designs provide a versatile and efficient means to boost item looks. Grasping in-mold decorations requires an all natural technique that thinks about all aspects of the manufacturing procedure to make sure success.

In the realm of production, the art of in-mold designs stands as a critical facet of item layout and manufacturing. Style advancement plays a crucial function in enhancing the visual charm, capability, and total high quality of products produced using in-mold decor processes.One of the vital elements of layout advancement in in-mold decorations is the assimilation of elaborate patterns, appearances, and graphics that were previously testing to achieve with standard decor techniques.Efficient production procedures are vital for converting the ingenious layouts developed in the field of in-mold decorations into high-quality completed items that meet market needs and customer expectations. Using personalization options such as personalized styles, shade variations, and textural elements can dramatically enhance the charm of in-mold decor products.